Made in Portugal

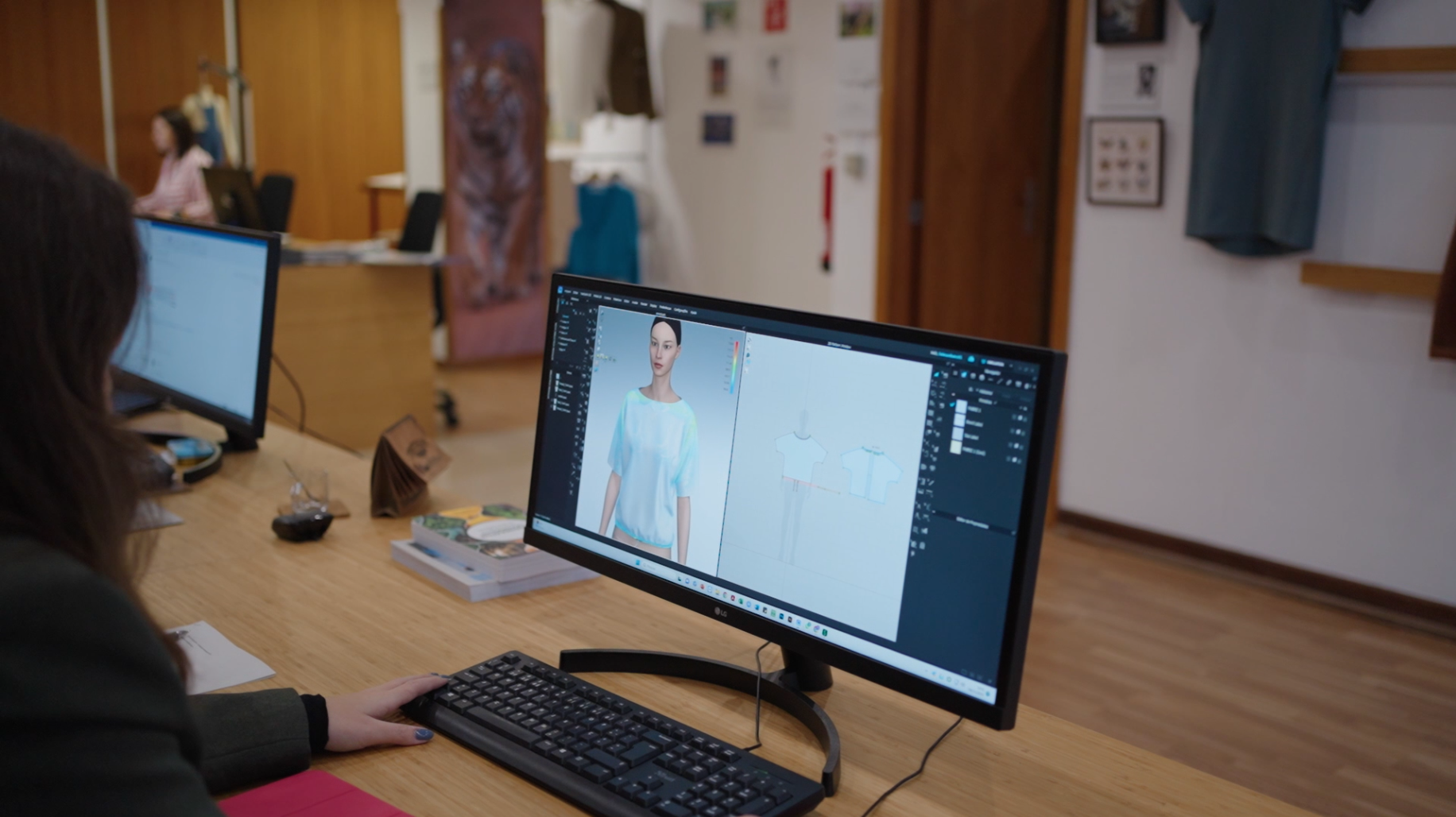

Innovation & Technology

Portugal has a solid and complete industrial infrastructure and as part of this infrastructure we have important partners contributing with research and development, innovation, testing and industrial feasibility studies.

Win-Win Textiles is a partner at CITEVE, a private NPO, which is a technology centre offering services to the industry within laboratory testing, product certification, technical and technological consultancy, R&D+innovation, training, software development and design. We are also a member of the Portuguese Textile Cluster, Cluster Têxtil, which is part of CITEVE. This support structure for the industry is focused on innovation and internationalization to increase the competitiveness of our sector and works internationally with other textile clusters on sharing knowledge and research.

Win-Win Textiles works with the university in our home town, Guimarães, University of Minho, with their textile engineering and design departments and we have made several projects together. We have also facilitated visits of students from KEA, Copenhagen School of Design & Technology, with whom we collaborate.

Please check information on our material sourcing & raw material innovation here.

In Portugal Win-Win Textiles has excellent conditions to innovate together with brands. We can put study groups together including the R&D partners above and combining their efforts with those of our partners from supply chains. This means that the brand can define a challenge (or we can give one to the brand) and we can all share knowledge and efforts in resolving the challenge. This can be avoiding specific fibres in products, finding new fibres, developping new products for a specific use with new methods to reduce or eliminate the use of petrochecimals. It could be focusing on a known impact of a product and finding ways to reduce it. Or substitute certain fibres, which have a negative impact or represent a certain risk, and developping new treatments to fabrics as a way to keep the performance levels in spite of the change of fibres.

Part of these projects also focus on residues from a brand’s production cycle and turning this resource into new products by recycling, upcycling or direct reuse for new products.

Portugal has the advantage of being able to do industrial testing at a very small scale through the University of Minho and CITEVE and at the same time we can scale industrially next door, once the feasibility has been proven. This does not only reduce costs, but also increases the speed at which we can make developments and innovate.

See also this section about circular economy.

We would be pleased to define projects with your brand. Please get in touch with Lars in this respect.