Introduction to Regenerated Cellulosic Fibres

Regenerated cellulosic fibres are made from cellulose that is extracted from wood pulp, which is then chemically dissolved and extruded as a continuous filament, which can be cut into staple fibres. They are called “regenerated cellulosic fibres” due to the combination of the natural raw cellulosic material and the chemical manufacturing process that breaks down the cellulose so it can be “regenerated” into a fibre from the original pulp. They are neither a truly synthetic fibre, in the sense of synthetics coming from petroleum, nor are they natural fibres, in the sense of processing fibres that are produced directly from plants or animals (such as wool). However, their properties and characteristics are more similar to those of natural cellulosic fibres, such as cotton, flax (linen), hemp and jute, than those of thermoplastic, petroleum-based synthetic fibres such as nylon or polyester. With an annual production volume of around 7.1 million mt, regenerated cellulosic fibers have a market share of around 6.4% of the total fiber production volume. The production volume has more than doubled since 1990 and is expected to further grow in the coming years.

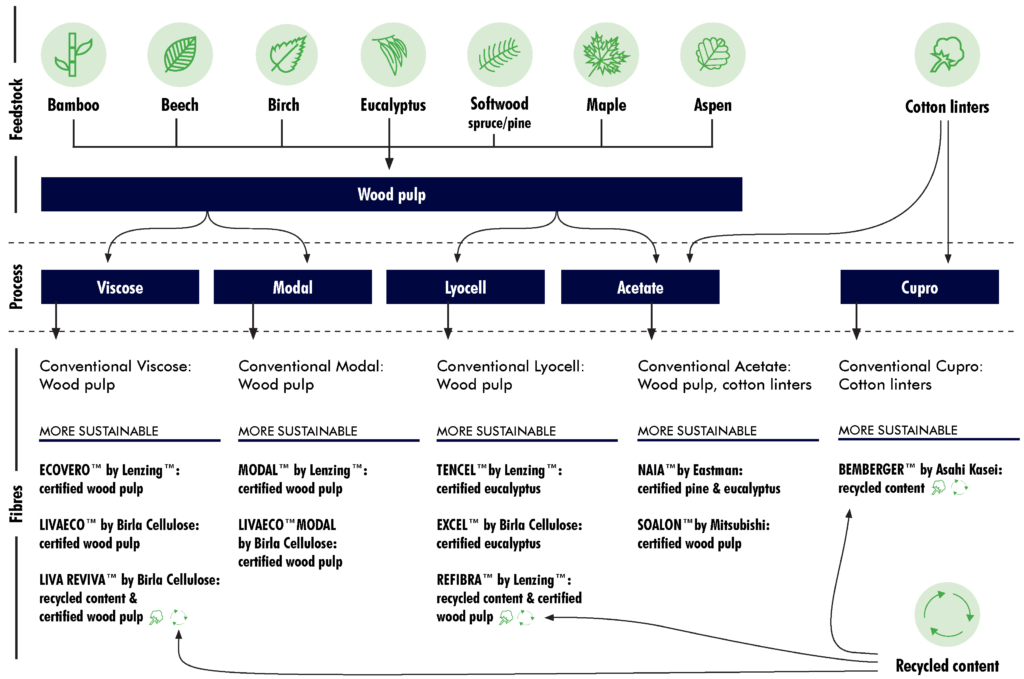

The feedstocks used for the production of the wood pulp, as well as the chemicals used in the dissolving process, have a significant impact on the sustainability performance of these fibres. In the figure below, you can see the most commonly used combinations of feedstock and chemical processes:

Feedstock

In theory, regenerated cellulosic fibres could be made out of any type of cellulose; however, the most commonly used feedstocks are bamboo, eucalyptus, beech, birch and softwood (spruce/pine). An exception are cotton linters used for the production of Cupro (more in the paragraph on Cupro).

Bamboo and eucalyptus have a much higher yield than all of the other trees, because they grow a lot faster. Furthermore, bamboo can also grow on land that cannot be used for food crops, which makes it a preferred feedstock for wood pulp used in the production of regenerated cellulosic fibres. Additionally, the forest or plantation where the trees are grown must be considered; it determines whether rainforest or other endangered forests have been deforested to make space for plantations and if the trees need irrigation or grow rain-fed. There are two major organisations, which set standards for sustainable forest management and offer certification: the Programme for the Endorsement of Forest Certification (PEFC) and the Forest Stewardship Council (FSC). The CanopyStyle Audits by the Canadian non-profit Canopy have become the leading assessment of regenerated cellulosic fibre suppliers on their raw material sourcing practices with the aim to protect ancient and endangered forests. Canopy estimates that half of the regenerated cellulosic fibres come from ancient and endangered forests.

Production processes

The production process from pulp to fibres is what differentiates the generic fibres by name: Viscose, modal, lyocell, cupro and (Tri-) Acetate.

The Sustainable Development Goals

When actively using our recommendations mentioned under more sustainable alternatives to conventional cellulosic fibres in the following text, brands will contribute to achieving the SDGs:

Conventional Viscose & Sustainable Alternatives

Recommendation

Win-Win Textiles recommends using viscose, which has been produced with less environmental impact, such as ECOVERO™ from the Austrian company Lenzing or Livaeco™ fibres by Birla Cellulose. Based on the Canopy Hot Button Issue 2018, around 60% of the wood pulp and 65-70% of the regenerated cellulosic fibre was manufactured in China. However, 84% of the regenerated cellulosic fibre producers have policies in place in line with the Canopy commitment to protect ancient and endangered forests. There has been renewed growth in the production of conventional viscose, and there have been several approaches to produce more sustainable viscose in recent years.

Production

Viscose is produced via a number of chemical processes, which transform the chips of hard wood into a cellulose wood pulp. The process is as follows:

- Once the trees have been harvested, they are converted into cellulose wood pulp by applying alkali chemicals such as sodium hydroxide (caustic soda) and sodium sulphide. These chemicals separate the substances that bind the wood fibres together.

- The pulp then undergoes further chemical soaking, ageing/oxidising and dissolving processes in order to create a solution.

- This solution is then forced through the fine holes of a spinneret into a bath of sulphuric acid.

- Once removed, the fibre is cleaned and ready to be spun.

Market situation

Conventional viscose is the most common regenerated cellulosic fibre with 79% market share and is readily available. Therefore, integration should be straight forward. With Birla and Lenzing covering 27% of the market share, the availability of more sustainable viscose should also be given. There is no certification for conventional viscose, which makes communication on products limited. However, Lenzing as well as Birla offer on-product communication through trademark labelling for their more sustainable fibre options. Both companies implemented block-chain technologies to enhance supply chain traceability and transparency. Viscose is a commonly used fibre and is readily available in large volumes, making it a cheap fibre. With continuing demand and increased production capacity largely in China, viscose is likely to remain a cheap fibre. The cost of more sustainable fibre options, however, remains higher.

Sustainability considerations

Conventional viscose uses significant amounts of water throughout its production and processing with a water footprint over 6,000% higher than polyester, but 54% less than conventional cotton. The manufacturing of conventional viscose is energy and chemical intensive since it requires numerous chemical processes to turn wood chip into a soft silky fibre. Viscose production can create highly contaminated wastewater effluent, which can contain high levels of organic compounds (VOCs) and hazardous acid gases such as hydrogen chloride that, if not correctly treated, can be dangerous to workers and toxic if released into the environment. Another big concern within viscose production is the feedstock. If the wood is sourced from forests not certified by the FSC or PEFC, sustainable forest management practices cannot be verified, meaning the trees could have been grown on land that competes with food crops or illegally logged from natural forests. The deforestation of ancient or endangered forests has been linked to the production of wood pulp to produce regenerated cellulosic fibres. Some wood species are less water and chemical intensive to grow than others; for example, bamboo and eucalyptus do not require much water and can be grown on ground unsuitable for food crops. The deforestation of natural forests can threaten the way of life of indigenous communities. Therefore, sourcing wood certified by FSC or PEFC helps to ensure that these communities’ livelihoods are protected. The more sustainable viscose fibre brands, ECOVERO™ by Lenzing and Livaeco™ by Birla Cellulose, are sourced exclusively from PEFC or FSC certified and controlled wood sources and produced with significantly lower fossil energy use and water than conventional viscose. Additionally, both fibres are fully biodegredable and can be traced back throughout the supply chain, ensuring transparency. ECOVERO™ branded viscose fibers are also certified with the internationally recognized EU Ecolabel.

Conventional Modal & Sustainable Alternatives

Recommendation

Win-Win Textiles recommends using modal, which has been produced with less environmental impact, e.g. LENZING™ Modal fibers or Livaeco™ MODAL from Birla Cellulose. The problems related to sustainable feedstock sources are the same for all regenerated cellulosic fibres. Modal is a second generation, modified viscose fibre with a higher tenacity profile, which allows the production of microfibres. Additionally, the fibres are more easily washable thanks to the fibre strength, but remain pleasantly soft to the skin.

Production

The production process of modal is similar to viscose, but with a few differences:

- Once the trees have been harvested, they are converted into cellulose wood pulp by applying alkali chemicals to separate the substances that bind the wood fibres together.

- The pulp is steeped in a sodium hydroxide solution and converted to alkali cellulose (spinning solution).

- The spinning solution (alkali cellulose) is then forced through a spinneret into a chemical bath.

- The fibres are then stretched, cut and bleached.

- The fibres are then cleaned and ready to be spun.

Market situation

Modal had a market share of around 2.8% of the total regenerated cellulosic fibre market in 2019, with a production of around 0.2 million mt. According to the Preferred Fibre and Material Report by the Textile Exchange, the compound annual growth rate (CAGR) of modal from 2017 to 2022 is estimated at about 9%. Modal is a well-established fibre, which is globally available and integration should be straightforward. With Birla and Lenzing covering 27% of the market share, the availability of more sustainable modal should also be given. There is no certification for conventional modal, which makes communication on products limited. However, Lenzing as well as Birla offer on-product communication through trademark labelling for their more sustainable fibre options. Modal is more expensive than conventional viscose; however, as demand and production capacity increase, its cost will inevitably reduce. More sustainable modal is considered to be a premium fibre, which means it comes at an even higher cost.

Sustainability considerations

The problems related to the sustainability performance of modal fibres are the same as for viscose; significant amounts of water throughout its production and processing, energy and chemical intensive, highly contaminated wastewater effluent and hazardous gases must be treated correctly. As with viscose, the feedstock is another big concern within modal production. If the wood is sourced from forests not certified by the FSC or PEFC, sustainable forest management practices cannot be verified, meaning the trees could have been grown on land that competes with food crops or illegally logged from natural forests. The deforestation of ancient or endangered forests has been linked to the production of wood pulp to produce regenerated cellulosic fibres and can threaten the way of life of indigenous communities. Therefore, sourcing wood certified by FSC or PEFC helps to ensure that these communities’ livelihoods are protected. LENZING™ only uses Austrian rain-fed beech trees for its production of LENZING™ Modal, which are FSC or PEFC certified. Furthermore, 95% of the chemicals used are recycled, and the manufacturing of LENZING™ Modal is CO2 neutral. The same sustainable forest management certifications account for Livaeco™ MODAL from Birla Cellulose. Additionally, Birla Cellulose claims to produce Livaeco™ MODAL with significantly lower Greenhouse Gas Emissions and water than conventional modal. Both fibres are fully biodegradable and can be traced back throughout the supply chain, ensuring transparency.

Lyocell

Recommendation

Among the regenerated cellulosic fibre production processes, lyocell is the most modern and most environmentally friendly. Therefore, Win-Win Textiles recommends the use of lyocell. Well-known lyocell fibres on the market are TENCEL™ by Lenzing and Birla Excel™ from Birla Cellulose. The problems related to sustainable feedstock sources are the same for all regenerated cellulosic fibres. Birla Cellulose and Lenzing both offer lyocell sourced from certified wood sources and prefer fast growing, local, rain-fed trees like eucalyptus, bamboo and beech. Another company working on lyocell manufacturing is Sateri, part of the Royal Golden Eagle (RGE) and one of the world’s largest producers of viscose. Since this is the most sustainable regenerated cellulosic fibre, there is a lot of innovation potential with new developments, especially within recycling. In 2017, Lenzing launched REFIBRA™, the first lyocell fibre made with reclaimed materials offered on a commercial scale. Initiated with 20% pre-consumer cotton residues in 2019 the share had increased to 30%.

Production

The general idea behind the lyocell process is to dissolve and process the pulp in a closed loop without any chemical derivatisation and with fewer production steps compared to conventional viscose production. For lyocell production, a non-toxic solvent is used to extract the cellulose from the wood pulp, which is almost entirely re-claimed, filtered and re-used.

- The cellulose is extracted directly from wood chips and dissolved into a bath of non-toxic solvent N-Methylmorpholine N-oxide (NMMO) and water. Any excess water is evaporated, leaving a cellulose solution behind.

- The solution is then filtered and extruded through spinnerets into a spinning bath.

- Auxiliary chemicals such as stabilisers and finishing agents may be added.

- The fibre is then cleaned and ready to be spun.

Market situation

With a market share of around 4.3% of all regenerated cellulosic fibres, and a production volume of roughly 0.3 million mt in 2019, lyocell was the third most used regenerated cellulosic fibre type after viscose and acetate. Based on a compound annual growth rate (CGAR) of 15% from 2017 to 2022, lyocell is expected to grow faster than any other regenerated cellulosic fibre. Conventional lyocell is not used as extensively as conventional viscose, but offered by the biggest regenerated cellulosic producers and hence readily available. This, in addition to the expected rise in demand, should make the integration straightforward. With Birla and Lenzing covering 27% of the market share, the availability of more sustainable lyocell should also be given. There is no certification for conventional lyocell, which makes communication on products limited. However, Lenzing as well as Birla offer on-product communication through trademark labelling for their more sustainable fibre options. Both companies implemented block-chain technologies to enhance supply chain traceability and transparency. Lyocell is more expensive than conventional viscose; however, as demand and production capacity increase, its cost will inevitably reduce. More sustainable lyocell is considered to be a premium fibre, which means it comes at an even higher cost.

Sustainability considerations

Although the manufacturing process is heavily reliant on large amounts of water, the growth of beech trees, eucalyptus trees and bamboo does not require irrigation, as they are rain-fed. Conventional lyocell is produced from wood chips, and therefore, the production process is relatively energy intensive. Nevertheless, lyocell production has fewer process steps and, thus, a shorter production time in comparison to conventional viscose, which helps reduce lyocell’s carbon footprint. Lenzing TENCEL® manufactured in Austria uses energy that is recovered from municipal incineration, whereas Birla claims to be the first company in the regenerated cellulosic fibre industry to be carbon neutral in Scope 1 & 2 GHG emissions. In the lyocell production process, non-toxic solvent N-methylmorpholine n-oxide (NMMO) is used, which can be reclaimed for re-use. However, the resulting wastewater from the production process must be treated sufficiently in order to ensure that no other hazardous substances enter the environment. It is important and commonly implemented that the wood is sourced from forests certified by the Forest Stewardship Council (FSC) or Programme for the Endorsement of Forest Certification (PEFC). Only then can sustainable forest management practices be verified and no ancient and endangered forest are at risk. Sourcing wood certified by FSC or PEFC also helps to ensure that indigenous communities’ livelihoods are protected. Furthermore, FSC and PEFC have established workers’ employment conditions, which adhere to the International Labour Organization (ILO) conventions regarding labour standards and promote decent working conditions. This includes prohibiting forced and child labour, the discrimination of workers, freedom of association and collective bargaining, as well as encouraging improved health and safety conditions. Since lyocell fibres have the most sustainable production process, companies producing lyocell tend to improve the entire supply chain’s sustainability performance and heavily invest in new technologies.

Cuprammonium Rayon (Cupro)

Recommendation

Win-Win Textiles recommends using Cuprammonium Rayon (Cupro), a fine filament fibre, when looking for a vegan alternative to silk. Cupro is a regenerated cellulosic fibre, manufactured using a similar process to viscose, but using 100% cotton linters, a pre-consumer residue of the cotton processing. It was developed at the turn of the century as an early alternative to conventional viscose. Cupro’s only remaining producer is the Japanese company Asahi Kasei who labelled its fibre Bemberg™. The fibre is certified with the Global Recycled Standard (GRS).

Production

Cupro differs from viscose in that it uses cotton linter (cotton seed fibres), copper salt and ammonia chemicals to produce a fine filament fibre:

- The linters are bleached using strong alkali solutions and purified under high temperatures, requiring large amounts of water and energy.

- These fibres are then dissolved in a solution of copper sulphate and ammonia, creating a highly viscous solution that is ready to be extruded through a spinneret.

- The solution is then neutralised with a sulphuric acid and stretched to produce cuprammonium rayon (cupro) fibre.

Market situation

Cupro remains a niche fibre, accounting for less than 1% of total regenerated cellulosic fibre production. Due to the high costs of inputs such as copper sulphate used in its manufacture, cupro remains relatively expensive and demand has continued to decline. The only producer of cupro, Asahi Kasei, has the capacity to produce up to 17,000 tonnes of Cupro per year. Cupro can be easily blended with other fibres and, as there is only one manufacturer, integration should be straightforward. Bemberg™ is OEKO-TEX 100 certified, but there is no on-product communication available. As Asahi Kasei is the only producer, traceability back to fibre processing should be straightforward. However, tracing the cotton linter to farm level could prove difficult, as cotton is often blended extensively before being processed. As a niche fibre, which relies on expensive inputs such as copper sulphate and, with only one global producer, Cupro remains relatively expensive compared to other fibres such as conventional viscose.

Sustainability considerations

Cupro’s production process is water intensive. This is because large volumes of water are used to produce pulp for spinning and also to remove copper salts and ammonia used in the manufacturing process. The production of cupro is an energy intensive process similar to viscose. In particular, the ammonia and copper sulphates used in the manufacture of cupro are energy intensive to produce. The embedded carbon in these inputs during their manufacture contributes significantly to cupro’s carbon footprint. However, Asahi Kasei’s Bemberg plant uses power generation facilities owned by Asahi Kasei, which produce 40% renewable energy. Asahi Kasei claims to be able to recover 99.9% of the copper in its solution, allowing it to produce cupro fibres with almost no new copper input. Cupro produced by Asahi Kasei is OEKO-TEX® Standard 100 certified, which helps to ensure its products are free from hazardous chemicals. However, if not recovered effectively, the copper and ammonia used in the manufacture of cupro can be hazardous if released into the environment. The direct land use associated with cupro production is negligible. Cotton linters that are used in the production of cupro are a by-product of cotton seed production, which would otherwise end up as waste. Bemberg™ is 100% GRS (Global Recycled Standard) certified and biodegradable.

Acetate & Triacetate

Recommendation

Win-Win Textiles recommends the use of (tri)acetate from sustainably sourced FSC, PEFC or SFI certified wood sources such as Mitsubishi’s Soalon™ or Naia™ by Eastman. Both producers have chemical systems (Bluesign and Zero Discharge of Hazardous Chemicals) in place, ensuring appropriate treatment and thorough recovery and reuse of the organic solvents used. Additionally, both fibres are OEKO-TEX 100 certified. Cellulose acetate fibres were among the earliest synthetic fibres based on cotton or wood pulp cellulose. (Tri)acetate fibres are usually multifilament fibres similar to rayon, but they are prone to melting. In 2020, Eastman additionally introduced a new staple fiber version of Naia™. Both Eastman fibers are also certified organic by the USDA (United States Department of Agriculture) and biodegradable, as well as compostable by TÜV Austria. Soalon™ is certified biomass by the Japan Organics Recycling Association. As a third company to look out for, ORANGE FIBER, an Italian startup, has developed a process to extract cellulose from the by-products of the citrus industry to produce fabrics made of acetate.

Production

Acetate and triacetate are mistakenly referred to as the same fiber since the fiber-forming substance is cellulose acetate; although, they are similar, their chemical compositions and formula differ. Triacetate is known as a generic description or primary acetate containing no hydroxyl group. Acetate fiber is known as modified or secondary acetate (diacetate) having two or more hydroxyl groups. Triacetate fibers, contain a higher ratio of acetate-to-cellulose than do acetate fibers. The process is as follows:

- Once the trees have been harvested, they are converted into purified cellulose wood pulp. Alternatively, cotton linters can be used as feedstock.

- The pulp then undergoes further chemical reactions in the presence of different acids and approximately 20 hours of ageing. It is then put through a controlled, partial hydrolysis in order to create acetate esters.

- The cellulose acetate flakes are then dissolved into a viscous resin (acetone) and forced through the fine holes of a spinneret.

- In the final dry spinning process, the solvent evaporates in warm air, and the filament fibres are ready to be spun.

Market situation

Acetate has the second biggest market share of around 13% of all regenerated cellulose fibres with a production of approximately 0.95 million mt in 2019, but it is mainly used for non-textile applications. As (tri)acetate is not as commonly used in textiles as viscose, modal and lyocell, it remains a niche fibre, and availability is limited. With Mitsubishi and Eastman, there are currently only two manufacturers of more sustainable acetate fibres on the market, and therefore, integration should be straightforward. Soalon™ and Naia™ are OEKO-Tex 100 certified, but there is no other on-product communication available.

Sustainability considerations

There is little third-party verified information on the sustainability performance of (tri)acetate other than company claims. As with all regenerated cellulosic fibres, (tri)acetate fibres have to come from sustainable feedstock (such as certified plantation forests or recycled cellulose) to be considered more sustainable. Additionally, the impact of hazardous chemicals used in (tri)acetate, such as sulfuric acid production, can be of concern from both a human health and safety and environmental pollution perspective if not treated correctly. Hence, the production process needs to be a closed-loop system that recycles the solvent used as claimed by Mitsubishi and Eastman. (Tri)acetate production differs from other regenerated cellulosic fibre production processes as it is dry spun, using less water. (Tri)acetate is made from a renewable resource and can be biodegradable under certain circumstances.

New developments/outlook

Certification

Bluesign has developed specific criteria for fiber production that were added to its “bluesign® Criteria for production sites” in March 2020, including criteria for feedstock, pulp and fibre production. ZDHC also launched several guidelines in April 2020, which measure the sustainability performance of viscose and modal production. Further standards that can be used for the pulp and/or fiber level include Cradle to Cradle Material Health Certificate Standard, STeP by OEKO-TEX, and the EU Eco Label. Another option is the production in compliance with the EU BREFs (BAT Reference Documents).

Initiatives

Several initiatives are supporting the transition to more sustainable regenerated cellulosic fibres. As mentioned before, Canopy works with the forest industry’s biggest customers and their suppliers to develop business solutions that address deforestation and protect forests. Changing Markets Foundation in collaboration with Earthworm launched a Roadmap towards responsible viscose and modal fiber manufacturing in February 2018. Fashion Positive just released the first-ever framework that defines Circular Materials with a special focus on regenerated cellulosic fibres, just to name a few.

Recycling

The market share of regenerated cellulosic fibres with recycled content is currently estimated at less than 1%. But the recycling of cellulose holds a lot of innovation potential, so it is expected to increase significantly for years to come. The first commercially available regenerated cellulosic fibres with a recycled content use mainly cotton linter like Asahi Kasei’s Bemberg™ cupro fibre or pre-consumer cotton textile waste like Lenzing’s Refibra or Birla’s Liva Reviva. As any other fibre with recycled content, the following certifications can be used: Recycled Claim Standard (RCS), Global Recycled Standard (GRS) and SCS Recycled Content Certification.

A few developments to look out for are:

- Ioncell by the Aalto university, a technology that turns used textiles, pulp or newspapers into new textile fibre, using a solvent called ionic liquid.

- Textloop technology by Circular Systems, which can mechanically recycle TENCEL™ lyocell.

- And NuCycl™, by the USA- based start-up Evrnu, a regenerated cellulosic fibre made from discarded clothing and textile waste.

- re:newcell transforms high cellulosic waste, such as cotton and manmade cellulosics, into dissolving pulp reusing the process chemicals and presented CIRCULOSE, a branded material made from 100% recycled textiles. The Swedish based company partnered with two of the biggest Chinese viscose producers Tanghan Sanyou and Sateri.